One Concept Provided • One Product Supplied

The only one-stop manufacturing and processing factory in Taiwan, mastering the core Know-how technology to provide OEM/ODM services for world-renowned brands, and the product quality reaches world-class standards. Wise Center has 30 years’ experiences, know-how in strong and effective R&D. Our Team has ability to receive one concept from client and output one product to client.

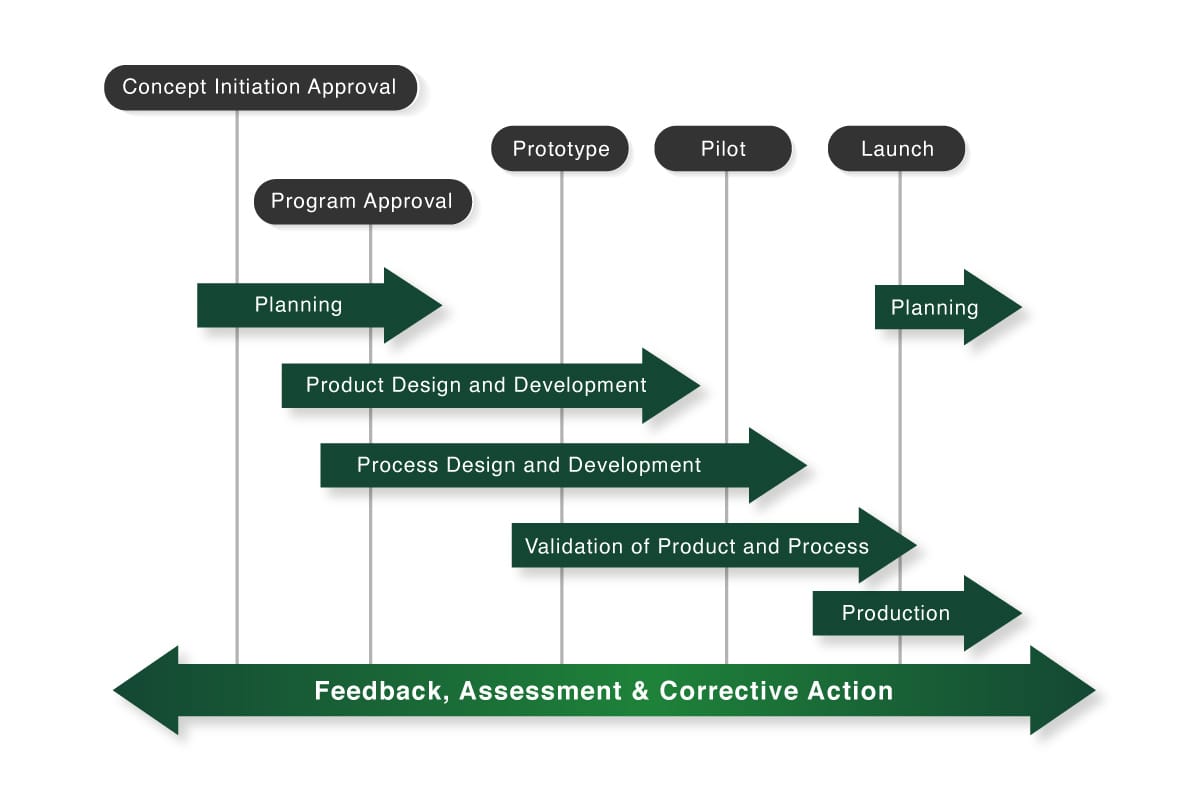

When receiving the customer's product design concept, we will first set up a research and development team, including R&D personnel, quality inspectors, production unit engineers, purchasing and sales personnel to discuss the feasibility of its development. After the plan is approved, there will be carry out product design and development, process design and development, product and process verification, trial mass production to order mass production.

Mr. Thomas Lin has great ambitions and ideals about the operation and maintenance of company and advocates three principles:

Sustainable Operation

Enable employees to work in a safe environment, a well-established welfare system and formulate complete management regulations; keep the principle of fairness and justice to subcontractors, and keep long-term partnership. The company has passed the EU BSCI (Environmental/Social Responsibility/Employee Benefits) certification.

Professional technology

Master one-stop manufacturing flow from raw materials to processing, remains the complete core technology, continue innovating, and pursue better quality.

Customer Care

Provide the best products to create better sales performance for customers from three directions as below:

- Establish a safe and hygienic environment and an employee welfare system.

- GS quality system certification.

- Promote the ISO9001:2015.

One Stop Manufacturing Process

01

Stamping

02

Heat Treatment

03

Grinding

04

Coating Painting

05

Assembling

06

Packing

07

Inspection

08

Warehouse

Product Materials

We produce stable and highly ranking horticultural-related products with Japanese SK5 and high carbon alloy steel which is output from R&D Alliance by CSC in Taiwan. The main advantage of the high-carbon alloy steel is its wear resistance, making its life 1.3 to 1.5 times that of general high-carbon steel.

Gear Transmission

We achieve to make the most effortless products by lower the mechanism’s friction with the study of the maximum leverage theory, so the power end shear is completely transmitted at the force application end. The gear-drive mechanism saves 30% of force compared to general product.

Blade Coating Process

Our blade is coated with PTFE, a non-stick technique, to have lowest friction coefficient, avoid oil stained, and become resistance to acid and alkali.